Welcome! In this post, we will delve into the concept of ‘blowing in insulation’, a method of insulating homes that offers numerous advantages. As homeowners, it’s crucial to understand how we can make our homes more energy-efficient and comfortable, while possibly saving on utility costs. This post aims to break down what ‘blowing in insulation’ is, its benefits and how it can be a game-changer for your household. Derived from expert opinion and fact-based data, this information promises invaluable insight. Whether you’re looking to improve your current home’s insulation or need guidance for a new project, this post will surely serve as a comprehensive guide. So, let’s dive in to enhance our understanding and make the best decisions for our homes!

Understanding the Basics of Blowing In Insulation

If you’re looking to make your home more energy-efficient, it’s time to consider blowing in insulation. This is a type of insulation that is literally blown into the cavities of your home’s walls, floors, and ceilings, helping to trap warm air inside during the cooler months and keep the hot air out during the summer. As a homeowner, understanding the basics of this process is crucial – not only can it help you reduce your energy costs, but it can also make your home more comfortable and eco-friendly.

So, where do you start? Let’s begin with the types of blowing in insulation.

Firstly, we have loose-fill fiberglass, which consists of small particles of spun glass that are blown into space. This is one of the most common types of insulation as it’s fire-resistant and non-absorbent.

Next, there’s cellulose, a plant-based material ideal for eco-conscious homeowners. It’s fire and insect resistant and has one of the highest R-values, which measures an insulation material’s resistance to heat flow.

Then we have mineral wool or rock wool, which is made up of fibers created from molten stone or industrial waste. These fibers trap pockets of air, slowing the flow of heat between your home’s interior and exterior.

Lastly, there’s loose-fill spray foam, an expanding material that fills nooks and crannies better than any other type. It’s particularly useful for insulating irregularly shaped areas and around obstacles.

| Blowing in Insulation Type | R-value | Common Use |

| Loose-fill Fiberglass | Moderate | Walls, Attics |

| Cellulose | High | Attics, Walls, Floors |

| Rock Wool | Moderate to High | Walls, Floors, Roof |

| Loose-fill Spray Foam | High | Tight Spaces, Irregularly Shaped Areas |

It’s important to note that each type of blowing in insulation has its pros and cons that can greatly affect its efficiency based on where it’s being used, your local climate, and your home’s specific needs. Considering these factors carefully will ensure that you truly optimize your home’s energy efficiency.

Choosing the Right Type of Blown In Insulation for Your Home

Understanding the different types of blow-in insulation

Blown in insulation, also known as loose-fill insulation, is a cost-effective and efficient way to insulate your home. The insulation material, which can be cellulose, fiberglass, or mineral wool, is blown into the cavities of the house like attics, wall cavities, and crawl spaces. It provides an excellent thermal barrier and it is eco-friendly since most of these materials are made from recycled waste materials. However, not all types are created equal. When it comes to selecting the right type of blown-in insulation for your home, careful consideration must be made.

Cellulose insulation is one of the most popular types. It is made of recycled newsprint and is treated with fire-retardant chemicals. It has a high R-Value (the measure of insulation’s thermal resistance), making it excellent for colder climates.

On the other hand, Fiberglass insulation is made from tiny glass fibers and is less dense. Hence, it generally has a lower R-Value. However, it is highly resistant to fire and moisture.

Finally, Mineral wool insulation is made from rock or blast furnace slag. This type of insulation is denser and more resistant to fire than the other two.

| Type | R-Value | Fire Resistant | Moisture Resistant |

|---|---|---|---|

| Cellulose | High | Yes | No |

| Fiberglass | Low/Medium | Yes | Yes |

| Mineral Wool | High | Yes | No |

Your home’s specific needs and climate should dictate your choice of blown-in insulation. For example, if you reside in a region with a hot and humid climate, fiberglass insulation might be the best choice due to its resistance to moisture.

Remember to consult with an insulation expert to select the most suitable type for your home. It is also advisable to check with local building codes as some types of insulation may not be permitted in certain areas.

Addressing the Common Questions About Blowing In Insulation

Perhaps one of the most frequently asked questions is about the procedure of blowing in insulation. This method involves the usage of a machine to pump insulating material into your house’s walls, attic, or floors. Interestingly, this material is typically cellulose, fiberglass, or mineral wool that have been broken down into loose fill for easy installation. The insulation works wonders for cutting down on energy costs and increasing comfort in your living space. Here are some common queries:

- Is blown-in insulation better than the traditional type? Blown-in insulation tends to be more efficient since it’s able to insulate hard-to-reach areas where traditional batts or rolls may not go.

- Can you do it yourself? Yes, for those who are handy, installing the insulation yourself could save money. However, to ensure effective coverage, professional help is recommended.

- How long does it last? Blown-in insulation can last for up to 20-30 years with proper care, making it a good long-term investment for your home.

The second set of popular inquiries focuses on the cost aspect of implementing this type of insulation. The cost of blowing in insulation varies based on several factors including your location, the size of your house and the specific type of insulation you choose. Also, the cost can change if you choose to hire professionals for installation. In the table below, we illustrate an estimate of the material and labor costs for a typical house:

| Insulation Type | Material Cost | Labor Cost |

|---|---|---|

| Cellulose | $0.60 – $0.80/sq.ft. | $1.50 – $2.50/sq.ft. |

| Fiberglass | $0.40 – $0.60/sq.ft. | $1.50 – $2.50/sq.ft. |

| Mineral Wool | $0.60 – $1.00/sq.ft. | $1.50 – $2.50/sq.ft. |

While these cost may look high initially, remember that blown-in insulation can contribute significantly to reducing your future energy bills. This investment will pay off in the long run through generous saving on heat and cooling expenses.

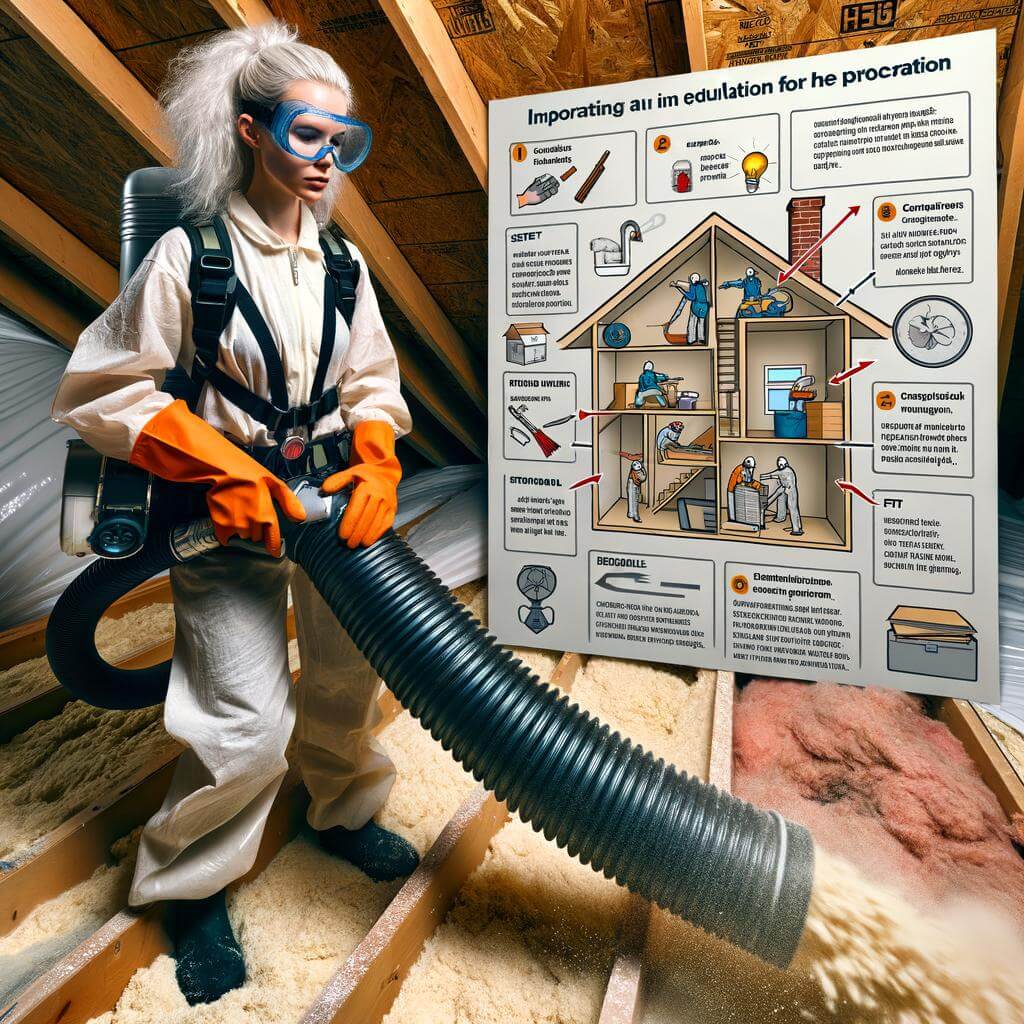

Detailed Steps in the Process of Installing Blowing In Insulation

In embarking on the task of installing blown-in insulation, it’s crucial to follow a careful procedure for a successful outcome. The first step involves a comprehensive home inspection. You’ll want to pinpoint the precise areas that require insulation. Take specific note of things such as electrical wires, recessed lights, and the types of existing insulation, if any. To avoid potential hazards or inefficiencies, you might need to add clearances or barriers.

And now – we’re onto the process of installing the insulation. The actual insulation blowing process isn’t too complex. You’ll need to have a machine available, which can often be rented from local home improvement stores. Always remember to follow safety instructions: wear a mask, goggles, gloves, and cover as much skin as possible.

- Step 1: Prepare the area. Make sure everything is clean and free of debris. Place plastic sheeting over any areas you want to protect from potential insulation overspray.

- Step 2: Set up the machine. This typically involves loading the insulation material into a hopper which then gets fed into a blower unit. The blower is what blows the insulation into your home.

- Step 3: Insulate! Move methodically starting from the farthest point and working your way towards the exit. This way you won’t have to step on any freshly insulated areas.

Let’s look at a simple table to understand the steps and required equipments:

| Steps | Required Equipments |

|---|---|

| Inspection | Flashlight, Inspection mirror, Notebook, Pen |

| Preparation | Plastic sheeting, Tape |

| Blowing Insulation | Insulation machine, Insulation material, Safety gear (goggles, mask, gloves, long sleeve shirt) |

Remember, while it’s entirely possible to conduct this process as a DIY project, there’s no harm in seeking professional assistance to ensure a safe and effective insulation installation.

Maximizing Energy Efficiency with Blowing In Insulation

If you seek an easy, cost-effective means to bolster your home’s energy efficiency, you might want to consider blowing in insulation. Unlike its traditional counterparts—fiberglass batts or blankets—the blown-in variant is designed to fill irregular spaces and tightly-sealed areas to offer superior energy savings. This type of insulation is loose-fill, typically made of cellulose, fiberglass, or mineral wool, and is installed with special blowing devices.

There are three primary types of blown-in insulation: fiberglass, cellulose, and mineral wool. Choosing the right one depends on your particular needs and budget. To aid you in making the best choice, we have provided a concise comparison below:

| Insulation Type | Advantages | Disadvantages |

|---|---|---|

| Fiberglass | Fire resistant, non-organic (won’t promote mold growth), lower cost. | Can irritate skin and lungs when disturbed. |

| Cellulose | Higher R-value (measures insulating power), made from recycled materials. | Can settle over time, possibly organic (may encourage mold growth if exposed to moisture). |

| Mineral Wool | Doesn’t require additional fireproofing, doesn’t promote mold or pest growth. | More expensive, may be difficult to install in tight spaces. |

Note that insulating your home also requires considering where exactly the insulation will be installed. Spaces such as attics, walls, and floors can hugely benefit from this type of insulation. A professional installer can offer advice tailored to your specific home layout and efficiency goals. Relying on a professional can also ensure the work is done correctly and safely, given that improperly installed insulation can lead to decreased performance and potential health hazards.

Safety and Maintenance Tips for Homes with Blown In Insulation

Understanding how to properly maintain your blown-in insulation is crucial for the safety and longevity of your home. To begin, let’s explore what blown in insulation actually is, before diving into best maintenance practices. Essentially, blown in insulation is an environmentally-friendly method of insulation that involves blowing or pouring insulation product into walls, attics, and floors. This type of insulation typically consists of cellulose, fiberglass, or mineral wool.

Let’s consider safety tips first. Minimize disturbance to the insulated areas, limiting access to only necessary activities. If you suspect the presence of vermin or pests, seek professional assistance, as they can compromise the effectiveness of your insulation. For optimal fire safety precaution, avoid placing any heat conductors near your insulation, as some materials used in blown-in insulation could potentially ignite.

| Maintenance Tips | Explanation |

|---|---|

| Regular Inspections | Inspect your blown-in insulation at least twice a year. Check for settling, wet spots, and damage from pests. |

| Proper Ventilation | Ensure your home has a proper ventilation system in place to prevent moisture buildup that could lead to mold and mildew. |

| Professional Services | While homeowners can carry out some maintenance tasks, it’s advisable to hire professionals for complex tasks like repairing or adding insulation. |

In terms of maintenance, keeping the insulation dry is paramount. Wet insulation can lead to growth of mold and mildew, which is detrimental to both your home and health. Ensure your home has good ventilation and any leaks or moisture issues are promptly addressed. Also, ensure that the insulation has not settled or degraded over time, compromising its effectiveness. A professional insulation service company can conduct these checkups for you and guide you on how best to maintain it.

Lastly, every few years, consider adding more insulation material to maintain the desired insulation level, but only if the existing insulation is in good condition. This will result in better conservation of energy and improved temperature regulation inside your home. Remember, proper maintenance and safety measures can help you maximize the benefits of blown-in insulation and prolong its lifespan.

Expert Tips and Recommendations on Blowing In Insulation

Nobody loves a chilly home during winter or a sweltering house during summer. The real solution to creating a comfortable house season in, season out is by providing an effective thermal barrier, and a popular option is blowing in insulation. With this technique, small particles of insulation are propelled into the wall cavities, attic spaces, and other hard-reach areas. The great thing about this method is it offers complete coverage with little or no material waste. However, it’s essential to consider several expert tips and recommendations before you embark on this task.

Creating a successful insulation barrier is about more than just the product; you need to consider the entire process. The first step is to ensure to seal all air leaks beforehand. It’s literally like throwing money out the window if you don’t. You should fill any openings around electricity cables, windows, doors, and pipes with caulk or expanding foam. Additionally, you will need to consider the Type of Insulation particularly in regards to material used. Material type can significantly impact the R-Value, which is a measure of thermal resistance.

| Type of Insulation Material | R-Value per Inch |

|---|---|

| Cellulose | 3.2-3.8 |

| Fiberglass | 2.2-2.7 |

| Rockwool | 3.0-3.3 |

The higher the R-Value, the better the insulation power. Lastly, keep in mind that safety should always be your utmost priority. Always remember to use proper safety equipment, including a mask, goggles, and gloves, and only entrust this job to a trusted, professional insulation installer to ensure a job well done.

To Conclude

In conclusion, ‘Blowing In Insulation’ is a proven, effective way to bolster your home’s energy efficiency, save money on utility bills, and enhance comfort indoors. By understanding how it works, the types of materials used, and the areas it best suits, you’re taking a proactive step towards boosting not just your home’s value but also its environmental credentials. Remember, though it might look simple, the process demands expertise. It’s always best to work with professional installers who have extensive experience in this field. As homeowners, our properties are our most significant investments, and every improvement counts. Stay informed, stay cozy, and let’s make our homes better, one insulation project at a time!