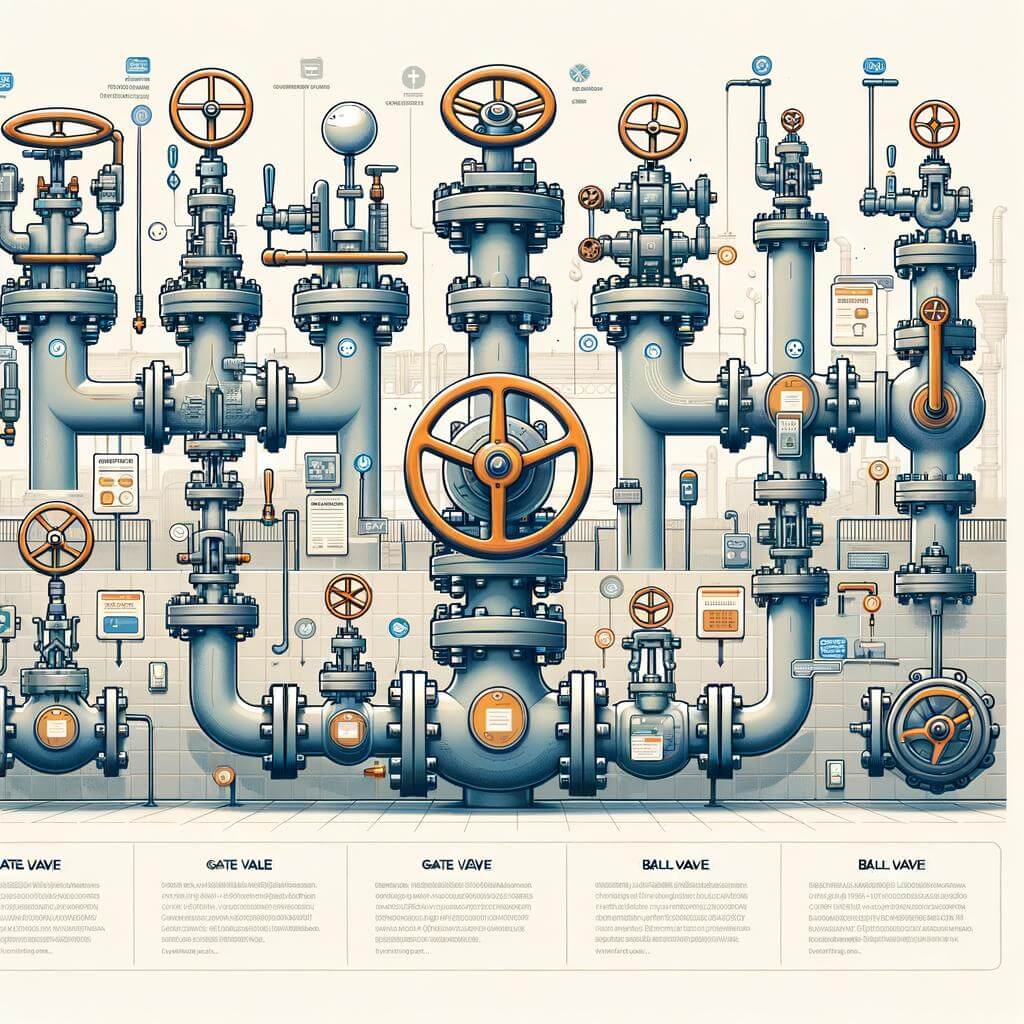

Welcome! In this educational and enlightening post, you will delve into the world of valves, specifically gate and ball valves. Some may view valves as mere pieces of equipment in a larger system, but it’s important to understand their specific role and function. We’ll be exploring the key differences between gate and ball valves, providing you with a clear, concise, and comprehensive comparison. By understanding these key differences, you can make more informed decisions about the right kind of valve to use for specific applications or projects. This can help improve efficiency, reduce costs, and potentially avoid unnecessary system failures. So, whether you are a seasoned engineer, an aspiring student, or someone simply interested in strengthening their general knowledge, you are sure to find our expert opinion and fact-based information extremely useful and readily applicable. Are you ready to learn more about gate and ball valves? Let’s dive in!

Understanding the Function and Structure of Gate Valves

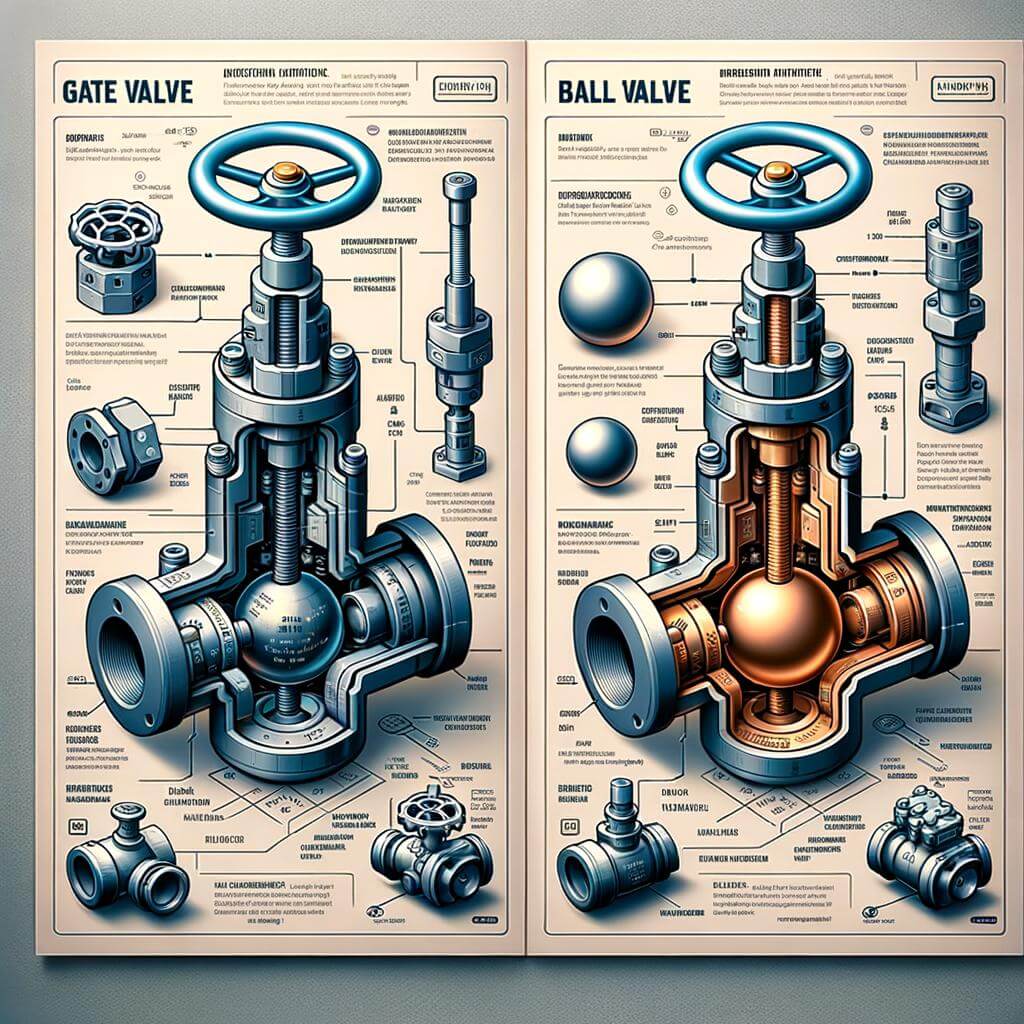

A gate valve, also known as a sluice valve, is a type of valve that opens by lifting a barrier (the gate) out of the path of the fluid. There are several key structural and functional features one must consider when examining gate valves, the first one being the valve’s body or shell. This is essentially the vessel that contains the pressure of the fluid and serves as the conduit system for the fluid to travel through. It is usually made of metal or plastic, with the latter more commonly used for smaller or less pressure-intensive valves.

The body of the valve houses several important components, including the “seat” or “disc”, which is the part that the gate seals against to halt the flow of fluid. Unlike ball valves, which create a seal through the rotation of spherical discs, gate valves seal by lowering the gate onto the seat. The other crucial component inside the body is the stem, which connects the handwheel or actuator at the top of the valve to the disc at the bottom. When the user turns the handwheel, the stem moves, which in turn either lifts or lowers the gate. The stem can be outside (OS&Y, where the stem’s position is visible) or inside (IS&Y) the valve bonnet. Other notable components of gate valves include:

- Bonnet: The cover on the valve body.

- Handwheel: Located at the top, used to operate the valve.

- Packing: Prevents leakage from the space between the stem and bonnet.

- Gland: This applies pressure to the packing material.

The key advantage of gate valves is their ability to limit flow disturbance and pressure drop in the system when fully opened, acting almost like a part of the pipe itself. They are typically utilized in applications where isolation is needed and throttling capabilities are not a requirement. However, their slow opening and closing times can be a disadvantage in some applications, making them less suitable for emergencies or instances where rapid shut-off is required.

Delving into the Operation and Design of Ball Valves

Ball valves are highly efficient and versatile, widely used in various industries for their flow control capabilities and durability. Characterized by their spherical design, these valves come with a hole or port right in the middle. Turning the handle of a ball valve rotates this inner ball, lining up the hole with the pipe to allow flow, or blocking it off when turned perpendicular to the pipe. The signature “quarter-turn” operation of the ball valve enables quick and easy on-off control, delivering superior seal performance even after many cycles.

While the ball valve’s operation may seem straightforward, what sets it apart from gate valves is its design. The ball valve is engineered to resist wear and tear, which minimizes maintenance requirements. Several factors make the ball valve particularly durable. The combination of a tight seal and a swift quarter-turn action reduces the likelihood of leakage, thereby prolonging the valve’s lifespan. Additionally, the materials used to construct ball valves, including alloys, stainless steel, and brass, contribute to their robustness and resilience.

- Spherical Design: Enables efficient flow control, easy on-off operation, and superior sealing.

- Quarter-Turn Operation: Provides quick control and prevents leakage, extending the valve’s life.

- Durable Materials: Constructed from alloys, stainless steel, brass for added resilience and longevity.

To illustrate further the differences between ball and gate valves, let’s take a glance at the following table.

| Valve Type | Operation | Design | Material | Best Use |

|---|---|---|---|---|

| Ball Valve | Quarter-Turn | Spherical | Alloys, Stainless Steel, Brass | High Pressure, Chemical Processing, Gas lines |

| Gate Valve | Multi-turn | Wedge-Shaped | Iron, Bronze, Plastic | Water and Waste, Low Pressure, Steam systems |

As you can see, while both ball and gate valves serve to control flow, they offer different strengths and are suited to different applications – a key factor to consider when selecting the right valve for your needs.

Key Differences between Gate Valves and Ball Valves

While both gate valves and ball valves are used to regulate the flow of liquids, they operate in slightly different ways, each with their distinct functionalities and applications.

Operational Mechanisms: A gate valve operates through a raising and lowering mechanism that either ‘opens’ by lifting the gate or ‘closes’ by lowering it to obstruct the flow. You can regulate the extent of the flow by adjusting the gate’s position. On the contrary, a ball valve works with a rotating ball. A hole in the ball aligns with the valve’s body when in the open position and obstructs flow when rotated by 90 degrees, offering only an open or shut option, with less control on the flow.

Applications: Due to their operational mechanisms, the valves have different applications. Gate valves are typically used in industries where a subtle regulation of flow is needed. This includes water treatment plants, irrigation systems, and certain manufacturing industries. Ball valves, on the other hand, are preferred in industries where quick shut-off is necessary. This includes chemical and gas industries, and HVAC systems.

| Factors | Gate Valves | Ball Valves |

|---|---|---|

| Operating Mechanisms | Raising and lowering of the gate | Rotation of the ball |

| Flow Control | Precise Regulation | Quick Shut-off |

| Common Applications | Water Treatment, Irrigation, Manufacturing | Chemical and Gas Industries, HVAC |

Go beyond these fundamental differences to find what fits your specific needs best. Factors such as pressure and temperature ratings, required maintenance, and cost, will also play a significant role in your decision-making process. Ultimately, the key is to understand the unique characteristics and advantages of each to leverage them in the most suitable applications.

Exploring Applications: Where Best to Use Gate and Ball Valves

Gate and ball valves may look similar at first glance, but they are designed for different applications. Understanding their unique properties will shine a light on the best use cases for each.

Gate Valves are designed with a ‘gate’ that can lower or raise to manage fluid flow. They work well for high pressure and high temperature environments, which makes them useful for specific projects. Some of their main applications include:

- Industrial piping systems

- Water treatment plants

- Oil and gas applications

- Power plants

| Gate Valves | |

|---|---|

| Best Suited For | High Pressure/Temperature environments |

| Main Applications | Industrial piping, Water treatment plants, Oil and Gas, Power Plants |

Moving on, Ball Valves come with a hollow, pivoting ball that controls fluid flow. These valves are known for their durability and the tight sealing, even with low pressure. As such, their best applications usually are:

- Chemical processing industry

- Pharmaceutical production

- Food and beverage industry

- Domestic plumbing systems

| Ball Valves | |

|---|---|

| Best Suited For | Low Pressure Environments |

| Main Applications | Pharmaceutical production, Food and Beverage, Chemical processing, Domestic plumbing |

Learning about the core differences between these two valve types allows you to make well-informed decisions when selecting the apt device for your operational needs.

Factors to Consider When Choosing between Gate and Ball Valves

To make an informed decision between gate and ball valves, several crucial factors need to be considered. First, think about what application the valve will be used for. Gate valves are better suited for applications that need a fully open or fully closed valve. They are not designed for throttling and can be damaged if used that way. On the other hand, ball valves are great for applications that require both throttling and full flow, due to their design and quick turn-off mechanism.

Next, consider the pressure and temperature ratings of the valve. Typically, gate valves have a higher pressure and temperature capacity, making them ideal for high-pressure system applications. In contrast, ball valves may not handle extreme high temperature and high-pressure environments well. Furthermore, think about the frequency with which the valve will be operated. If you’re likely to operate it regularly, it might be worth investing in a ball valve, which generally withstands frequent use better.

| Valve Type | Best Used For | Pressure and Temperature Capacity | Frequency of Operation |

| Gate Valves | Applications requiring full open or close | Ideal for high-pressure systems | Prefers infrequent use |

| Ball Valves | Applications requiring both throttling and full flow | May not handle extreme conditions well | Withstands frequent use better |

The durability and maintenance requirements of the valve should also be assessed before purchase. Generally, gate valves are more prone to wear and tear because their sealing surfaces rub together. They may require more maintenance than ball valves, which have an inherent self-cleaning feature called “wipe action”. Finally, it’s also wise to look at the cost. Although ball valves are often more expensive upfront, they may save you money in the long run due to less required maintenance and longer service life.

Expert Recommendations: Making the Right Valve Choice for Your Project

Choosing the appropriate valve for any project can be a daunting task given the array of options. The decision significantly influences the performance, safety, and success of the project. Among all types, Gate and Ball Valves are often at the center of the selection process. Understanding the key differences between these two can help guide your choice. Gate valves are designed for free flow or shut-off of the fluid, they are not intended to control the flow midpoint. They are durable and preferred for their capability to halt liquid flow entirely – ideal for projects where total isolation is required.

| Gate Valves | Ball Valves | |

|---|---|---|

| Flow control | Efficent but not for mid-point flow control | Excellent, even for mid-point flow control |

| Durablity | Highly durable | Durablity varies |

| Suitability | Best for total isolation requirement | Ideal for quick shut on and off |

On the other hand, Ball valves feature a spherical disc with a hole in it, which allows for the excellent control of flow, including mid-point flow control. They provide a swift shut on and off, making them suitable for projects with quick operation requirements. However, their durability varies and is often less than that of gate valves. The below considerations are worth evaluating while deciding between a gate and a ball valve:

- Type of fluid: For slurries and viscous liquids, gate valves are preferred due to their better passage ways.

- Operation speed: Ball valves are more suited for situations where fast operation is valued.

- Cost: Gate valves are generally less expensive than ball valves.

- Maintenance: Ball valves require less maintenance and are easier to repair.

In conclusion, gate valves and ball valves both have their strengths and limitations. Understanding these is crucial to make an educated valve selection for your specific project.

In Summary

In conclusion, understanding the unique features and functionality of both gate and ball valves is crucial when making decisions about which to use in various applications. Utilizing this expert guide, we trust you can now tell these two apart, weighing their pros and cons to suit your specific needs effectively. Remember, gate valves are best suited for on-off applications, offering low-cost and minimal pressure drop, whereas ball valves are ideal for throttling capabilities and provide more secure sealing. It’s all a matter of the purpose, requirements, and conditions of your system. We sincerely hope that this article has shed light on this subject, clarified your queries, and will be a useful reference for your future endeavors. Stay informed, and make your choices wisely!