Welcome, esteemed readers! In this informative post, we will be dissecting the importance of descaling cast iron pipes in depth, guided by an expert’s insight. Cast iron pipes are known for their longevity and durability, but like everything else, they need regular maintenance to keep functioning at their best and descaling is a crucial part of that maintenance. Left untreated, scale build-up can lead to severe pipe damage and costly repairs. Understanding this essential process can help homeowners and business owners save significant time, money, and avoid potential plumbing disasters. Let’s dive in, and uncover why descaling cast iron pipes is absolutely critical from an expert’s perspective. This post promises to be insightful, easy to understand, and incredibly helpful.

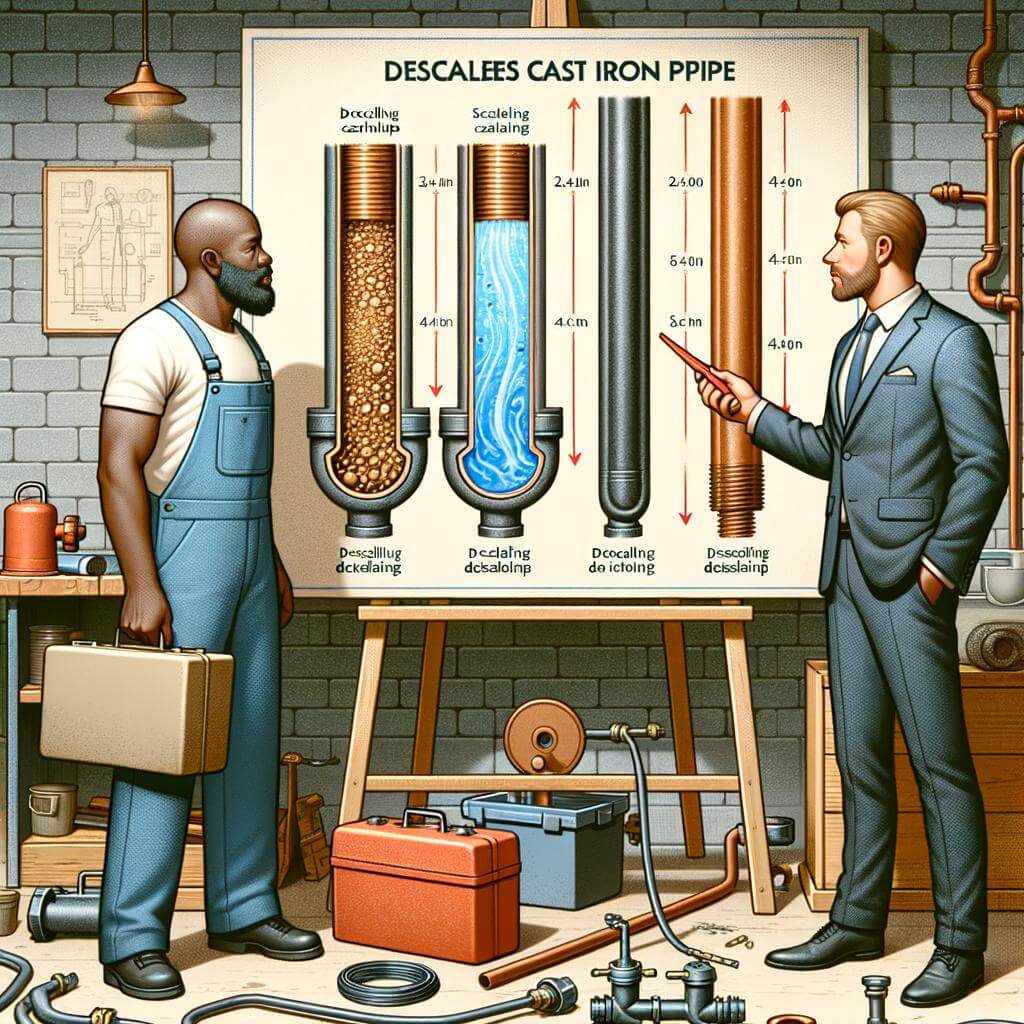

Understanding the Importance of Descaling Cast Iron Pipes

Cast iron pipes, due to their strength and durability, have been an essential component in plumbing systems for centuries. Over time, however, these pipes can scale, leading to decreased performance and eventual pipe failure. Descaling which involves the removal of accumulated minerals, is a critical maintenance process for cast iron pipes to maintain water flow and prevent leaks. Here’s why you need to pay attention:

Much like cholesterol blocking arteries in the human heart, scale buildup in cast iron pipes restricts flow and forces the system to work harder. This increased strain can lead to accelerated corrosion, increased water pressure, and ultimately, pipe failure. Descaling these pipes regularly helps maintain the pipe’s functionality, reduce repair costs, and ensure a long lifespan for the system.

| Issue | Description | Solution |

|---|---|---|

| Restricted Flow | Scale buildup restricts water flow, requiring more energy for the system to function. | Regular descaling helps maintain optimal water flow. |

| Increased Corrosion | Without descaling, pipes corrode faster due to layers of minerals exacerbating corrosion rates. | Descaling removes these minerals, slowing the corrosion process. |

| Increased Repair Costs | Scaled-up pipes are prone to leaks and damages that require expensive repairs. | Prevention through descaling can save significant repair costs. |

Remember, pipes are at the heart of any functional plumbing system. Their wellbeing impacts not only the efficacy of your system but also your bottom line. Treat them with the care they deserve by incorporating descaling practices into your pipe maintenance routine. Your pipes, and your wallet, will thank you!

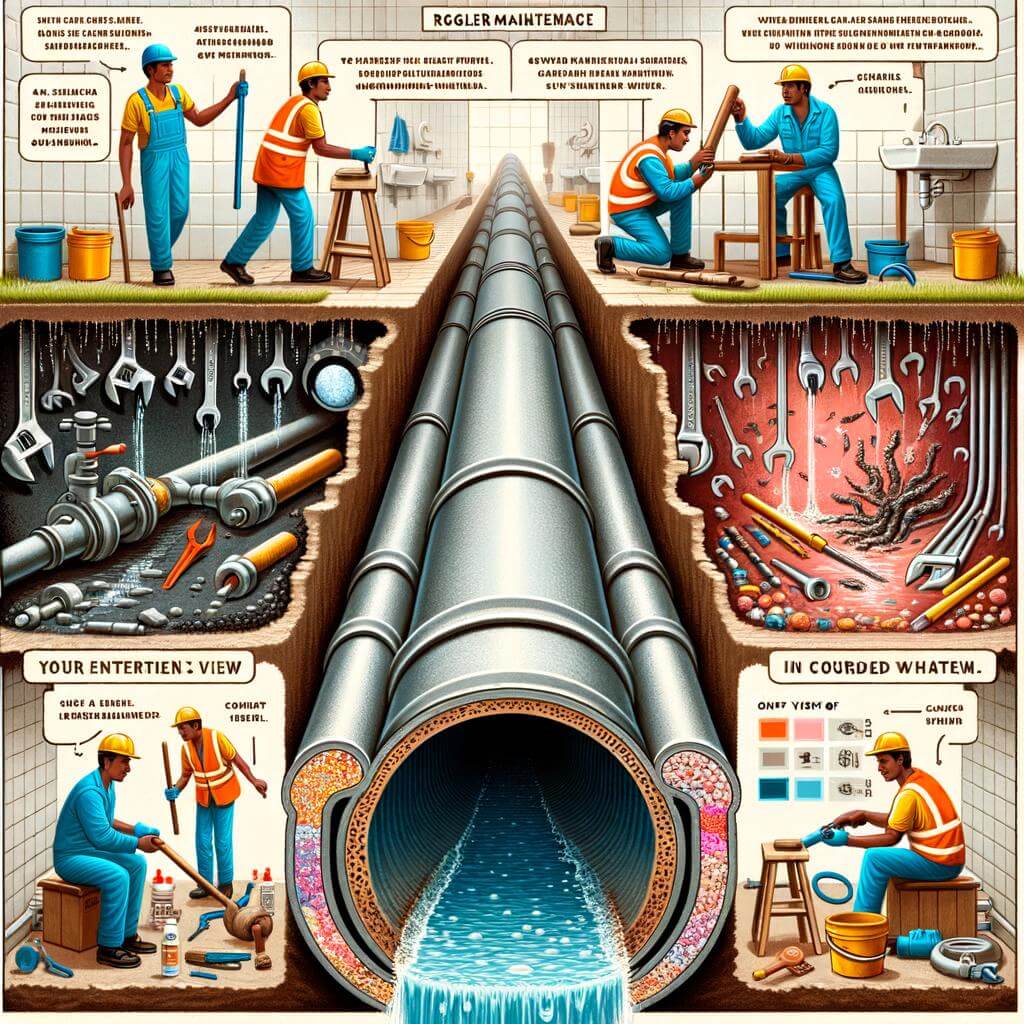

The Necessity of Regular Maintenance for Cast Iron Pipes

There is no denying that cast iron pipes are durable and long-lasting. Their sturdy structure makes them an excellent choice for various applications, particularly for transporting water, gas, or waste. However, like any other building material, these pipes require regular care and maintenance. This includes consistent descaling. It may feel like an unnecessary hassle, but the long-term benefits it offers are significant.

Descaling is the process of removing unwanted deposits, specifically scale build-up, from inside the pipes. Reduced water flow and clogging are two major problems that arise from not regularly descaling your pipes. Other repercussions include foul odours, leaks, and even pipe failure. But what causes these issues? Here are some common factors:

- Water chemistry: High mineral content, particularly calcium and magnesium, can lead to scale build-up.

- Temperature: High temperature speeds up the corrosion process, causing more scaling.

- Flow rate: Slow-moving water allows more time for minerals to settle and form scales.

These unwanted challenges and potential damage caused by scales underline the importance of descaling. Performing this cleaning process extends the life of your cast iron pipes, ensuring that they efficiently perform their intended function.

Let’s visualize the benefits of descaling your pipes in a table:

| Benefit | Description |

|---|---|

| Increased Lifespan | Properly maintained pipes can significantly outrun their expected lifespan. |

| Improved Efficiency | Removal of scales helps in restoring the pipe’s original capacity, ensuring optimum flow rate. |

| Cost-Efficient | Preventive measures like descaling avert problems that can lead to expensive repairs or replacements. |

| Environmentally Friendly | Regular maintenance reduces the chances of leaks, hence preventing waste and potential environmental harm. |

Potential Issues with Neglecting Cast Iron Pipe Descaling

One of the major problems resulting from improper maintenance of cast iron pipes is the inevitable pipe corrosion. Because cast iron is a metal, it oxidizes in the presence of water, leading to rust formation and pipe deterioration over time. If left unchecked, this can lead to pipe leakage or burst pipes, resulting in costly repairs and potential damage to your property. Regular descaling can help prevent this by removing the buildup of minerals, corrosion, and other sediment, improving the lifespan and performance of your cast iron pipes.

Moreover, neglecting descaling can lead to health and sanitary issues. As scale buildup continues to clog the pipe, this can cause sewage backup, affecting the plumbing system’s efficiency. This not only leads to foul odors and unsanitary conditions, but can also pose serious health risks due to the potential spread of harmful bacteria and pathogens. Furthermore, as the flow of water is restricted, it may increase the likelihood of water contamination, affecting the quality of your water supply.

- Regular Descaling: Prevents pipe corrosion, leakage, and damage to property.

- Health and Sanitation: Averts sewage backup, foul odors, bacterial spread, and water contamination.

| Descaling Frequency | Benefits | Adverse Effects (If Neglected) |

|---|---|---|

| Regularly (6-12 months) | Long lifespan & efficient plumbing | Pipe corrosion & property damage |

| Often (1-3 months) | Prevents sewage backup & bacterial spread | Foul odors & potential health risks |

The downsides of neglecting cast iron pipe descaling are abundant and serious. Regardless of whether you’re a homeowner or property manager, it’s essential to regularly perform this maintenance task to ensure the longevity and efficacy of your plumbing system while maintaining a sanitary and safe environment. Regular descaling can save you from unnecessary hassle and expense in the long run.

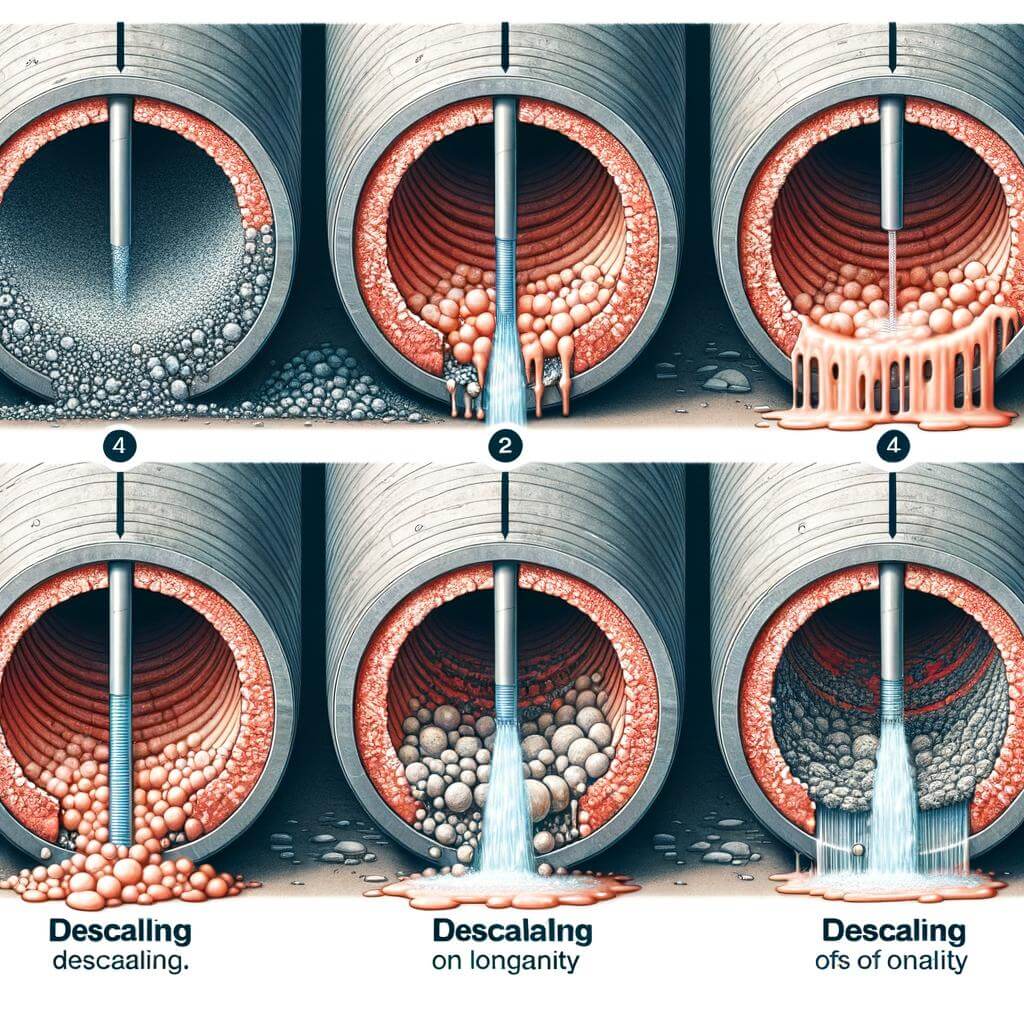

Expert Analysis: The Direct Effects of Descaling on Pipe Longevity

Pipe longevity is a crucial factor in both industrial and domestic sectors. The quality and lifespan of pipes significantly affect the efficiency of systems using them. One key method to prolong pipe life span is descaling. Descaling is a process of removing buildup or residues that accumulate inside pipes over time obstructing the flow of water, industrial chemicals, or gases. These residues can be in the form of minerals, rust, or other substances that drastically hamper the overall functionality of pipes.

- Descaling contributes to uninterrupted flow, eliminating blockages caused by accumulated scale.

- Damaged or weak areas in pipes are more easily identified and addressed during descaling, leading to early detection of potential issues.

- Descaling can prevent corrosion that significantly shortens the lifespan of cast iron pipes.

| Effect | Without Descaling | With Descaling |

|---|---|---|

| Flow consistency | Decreased flow due to obstruction | Smooth, uninterrupted flow |

| Early problem detection | Harder to identify potential issues | Easier identification and early remediation |

| Corrosion prevention | Increased risk of pipe corrosion | Decreased risk of corrosion |

| Longevity | Shortened lifespan | Extended lifespan |

Timely descaling of cast iron pipes greatly enhances pipe longevity by preventing scale buildup that could lead to weak spots and fractures. Furthermore, it boosts system efficiency by ensuring a smooth and uninterrupted flow. As an essential maintenance activity, it helps avoid costly repairs or replacements down the line. Thus, de-scaling contributes directly to the overall durability and longevity of cast iron pipes, making it critical to both increasing performance and reducing long-term costs.

Proactive vs Reactive: The Cost-Effective Benefits of Routine Descaling

Understanding Proactive vs Reactive Descaling

When dealing with cast iron pipes, corrosion is often an inescapable reality. However, the way plumbing maintenance is addressed often influences the longevity of your pipes and the overall cost efficiency. Here, we focus on two approaches to pipe upkeep: proactive and reactive.

The reactive approach involves waiting for noticeable symptoms of an issue before taking corrective action. While this may seem cost-effective in the short term, it often results in significant costs due to major repairs or replacements. The damage is often more extensive and harder to control because of the delayed intervention. The proactive approach involves regular routine maintenance, in this case, descaling, to keep pipes optimal. Sure, you might spend on maintenance, but you save significantly in the long run by avoiding serious pipe damage.

Routine Descaling: A Cost-Effective Solution

Routine descaling of your cast iron pipes plays a significant role in preventing rust and corrosion build-up. Pipes often perform better and last longer when regularly cleaned and descaled. The process involves using appropriate solutions or tools to remove layers of scale build-up within the pipe, hence reducing the chance of blockages and maintaining optimal performance.

It’s important to note that proactive descaling is cheaper than reactive pipe replacement or repair. Naturally, the cost of descaling will depend on the size of the task, the complexity of the plumbing system, and whether a professional is conducting the descaling.

| Task | Descale | Replace |

|---|---|---|

| Cost | Low | High |

| Time | Short | Long |

| Disruption | Minimal | Significant |

In conclusion, being proactive in your maintenance and adopting a consistent descaling protocol not only enhances pipe longevity but is also more cost-effective in the long run. Reactive repairs, on the other hand, can be significantly time-consuming and more costly due to an increase in materials and labor required for major repairs or replacements. A shift to a proactive approach could mean significant savings and fewer headaches for homeowners.

Choosing the Right Professional for Your Cast Iron Pipe Descaling Needs

When it comes to descaling cast iron pipes – it is essential to have a meticulous and thorough process. This responsibility should fall onto the shoulders of a seasoned professional who is well-versed with the intricate details of pipe servicing. A specialist, who possesses a wealth of knowledge, skills and experience, can accurately identify the nature and extent of the scaling issue in your pipes and subsequently, employ the most effective solutions in a timely and efficient manner. Execution through a seasoned professional ensures minimum disruption to your daily life while garnering the best results.

Understanding the critical factors to consider while choosing a descaling service can greatly benefit the longevity and performance of your pipes. Check for the professional’s accreditations and licenses, customer reviews and testimonials, years of experience, and their approach to safety. An expert service provider would prioritize these aspects:

- Technical knowledge: Comprehensive understanding of different pipe materials, their potential issues and appropriate descaling techniques.

- Relevant experience: Proven track record of successfully conducted pipe descaling projects.

- Professional credentials: Necessary licenses and certifications.

- Customer satisfaction: Positive feedback and high ratings from previous customers.

- Safety measures: Adherence to safety guidelines and use of protective equipment.

| Criteria | Why it’s important |

|---|---|

| Technical knowledge | Determines the quality and efficiency of descaling work |

| Relevant experience | The more experience, the higher the likelihood of successful outcomes |

| Professional credentials | Ensures the service provider meets industry standards |

| Customer satisfaction | Reflects service quality and reliability of the professional |

| Safety measures | Prevents accidents and hazards during the descaling process |

In conclusion, the selection of your service provider is just as important as the descaling process itself. Choose a professional with a firm understanding of the cast iron pipes and a proficient skill set to ensure an effective and smooth descaling operation.

Concluding Remarks

In summarizing, de-scaling cast iron pipes is an essential practice that is too often overlooked. This process ensures proper pipeline function, mitigates future plumbing issues, and ultimately, substantiates the longevity and efficiency of your system. By prioritizing regular maintenance, homeowners and business owners alike can avoid unnecessary costs and inconvenience.

We hope this article has provided useful, accessible information about why the de-scaling process is so central to the overall health of your pipes. Armed with this knowledge and expert insight, you can make informed decisions to safeguard your property’s infrastructure and maintain an efficient and effective sewage system. Remember, proactive care is the key to preventing damage and preserving the integrity of your plumbing.

We encourage you to seek professional help when dealing with pipe maintenance or de-scaling, ensuring that the job is completed correctly and safely. As always, our goal at [Your Publication or Company Name] is to equip you with the information you need to take proactive measures in caring for your home or business. We invite you to explore additional resources on our site and reach out with any questions or concerns. Thank you for reading, and happy plumbing!